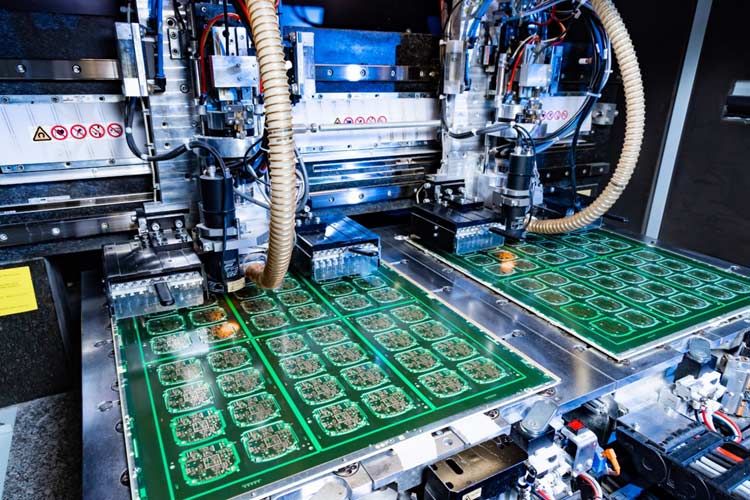

In the rapidly evolving world of electronics, Printed Circuit Boards (turnkey pcb assembly) are the unsung heroes that power our digital lives. PCBs are the heart and soul of modern gadgets, from smartphones and laptops to advanced medical devices and automobiles. These compact, intricate boards are a testament to the remarkable advancements in technology, both in terms of design and fabrication. In this article, we delve into the art and science of PCB fabrication, highlighting its crucial role in our daily lives.

The Blueprint of Innovation: Designing PCBs

PCB fabrication begins with the design phase, where engineers and designers meticulously plan the layout and connections of components on the board. Cutting-edge design software, like Altium Designer or Eagle, enables designers to create a blueprint for the PCB. It’s in this stage that the PCB’s functionality, size, and shape are defined, ensuring it fits perfectly within the final product’s constraints.

Materials Matter: Selecting the Right Substrate

One of the critical decisions in PCB fabrication is choosing the right substrate material. Common choices include FR-4, a widely used epoxy-based material, and flexible substrates for bendable PCBs. The material chosen can significantly impact the board’s performance, durability, and cost. Proper selection is key to ensuring the PCB meets the product’s specific requirements.

Etching the Magic: Layering and Circuitry

Once the design and substrate are finalized, it’s time to bring the PCB to life. A layering process begins, where thin copper sheets are laminated onto the substrate. The next step involves using chemical etching to remove excess copper, leaving behind the intricate circuitry that will carry electrical signals throughout the board.